Posts selected fromManagement Blog - Engineering Blog - Investing Blog and other blogs - The Customer Knows Best?

Some management ideas are pretty easy and straight forward. But many management practices require knowledge and judgment to apply them successfully. Easy solutions may be desired, but, often you must choose between easy and effective (hint, I suggest effective is the better target).

Listening to customers is important but it is not sufficient.

...

People could assume the numbers at Enron proved what Enron was doing was correct. But it did not prove that. Until we start to evaluate data more accurately we will continue to mistakenly see proof where it does not exist. continue reading: The Customer Knows Best? - Brainstorming Under Attack

Brainstorming is about creating an opportunity to bring new ideas the forefront.

There are other useful tools such as the affinity diagram which can serve as another option (or can serve as a tool to work with the results of brainstorming).

And Edward DeBono has excellent creativity tools, like his 6 thinking hats. Brainstorming is a useful tool when applied properly but it is only one tool and other tools should be used also. continue reading: Brainstorming Under Attack - Lean, Mean, Six Sigma Machines

What management claims as the reason for results is not necessarily actually the reason (and this is true not just if they say forced ranking is good [which I disagree with] or lean thinking is good [which I agree with]).

A great difficulty in evaluating management concepts is that the complexity (including interaction) makes it very difficult to determine the results of specific management decisions (separating out the effects of one or several decisions from the hundreds that were made and outside influences, etc.). How much of the success of Google is due to the 20% “engineer time.”Can you calculate the return? I don’t think so. But you can make a judgment that it is a benefit. continue reading: Lean, Mean, Six Sigma Machines - Lean Beyond the Factory Floor

Experts (in TQM, Deming’s idea’s, Six Sigma, BPR, Lean…) always stress the importance of involving not just others (when talking to management) but their (managers) work too. But fairly consistently management adopts improvement ideas mostly for others, not for their own work. As organizations apply management improvement ideas on some portion of the work the talk of going beyond “factory floor” improvements becomes more common as improvements are seen where it is applied.

Fast Cycle Change in Knowledge-Based Organizations by Ian Hau and Ford Calhoun, Jun 1997 is a good example of lean thinking, eliminating waste… outside the factory floor. continue reading: Lean Beyond the Factory Floor - Kleptocrat CEOs and Their Apologists

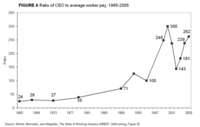

CEOs, and their cronies, were well paid decades ago. As their greed about their pay got to be unethical Peter Drucker started to speak out against their ethical failures. As those abuses became more extreme he increased his objections.

...

I want a CEO that is paid well and seeks their reward not by taking from the corporate treasury but by providing great jobs, customer happiness and an improved society. continue reading: Kleptocrat CEOs and Their Apologists - Management Advice Failures

I share this frustration with declaring old ideas new: Management Improvement, Better and Different, Quality, SPC and Your Career, Deming and Six Sigma, Management Lessons from Terry Ryan, Everybody Wants It, Toyota’s Got It, Fashion-Incubator on Deming’s Ideas and on and on.

Why does this matter? Two reasons, most importantly to me is that when we fail to value the best ideas, instead valuing the new ideas, we are not as effective as we could be. We often accept pale copies of good old ideas instead of going to the good old ideas – which will often lead to a much richer source of knowledge. When I compare copyrighted versions of management thinking to ideas from people like Ackoff, Deming, Ohno, Scholtes, McGreggor the depth and richness of those I admire is much greater than the packaged solutions as I see it (and they are often more concerned with furthering the practice of management than further their brand). Second, it is often dishonest, or at least sloppy thinkers, that don’t acknowledge the history of management ideas. continue reading: Management Advice Failures - Companies in Need of Customer Focus

My brother has suggested several times I should arrange for companies to pay me to point out their weaknesses (and suggest improvements). I wish I could get them to do so.

Often 1 interaction with their customer service is enough to provide examples of several systemic weaknesses in how customers are treated. continue reading: Companies in Need of Customer Focus - More on Obscene CEO Pay

Unfortunately this reverse robin hood (steal from the workers, stock holder, customers…) and give to the CEO tale continues. Hopefully someday soon we can at least turn the momentum in the right direction (stopping these incredibly excessive “pay” packages). Even then it will take quite a deal of reducing these ridiculous “pay” packages to reach some sense of decency. continue reading: More on Obscene CEO Pay - Toyota IT for Kaizen

IT often does the opposite of lean management and makes things more complex, more prone to error, less effective, etc.. Often all in search of only one thing – cutting costs. For that people should not be faulted for being skeptical of IT solutions. However, that does not mean that IT cannot play a part in improvements. It can, just be careful.

I find it a good sign when the CIO office is helping people find solutions at the request of the users rather than dictating solutions from on high. Some of the dictating might be necessary to optimize the system of IT (some local sub optimization may be required for the overall good) but in my opinion this is used as an excuse far too often.

Related: The Edge-case Excuse (a post I wrote more recently on the topic of error prone IT solutions) continue reading: Toyota IT for Kaizen - Our Policy is to Stick Our Heads in the Sand

The failure to adapt to a changing world (the internet is here to stay folks) is amazing. Most companies would benefit from just adapting to the changing world without elaborate innovation plans. Innovation is great, but challenging. Don’t ignore the possible improvements short of innovation. continue reading: Our Policy is to Stick Our Heads in the Sand - Is Innovation Needed to Keep Manufacturing in the USA?

There is no ace in the hole. If countries want to keep manufacturing jobs they are going to have to do lots of things right. No country has such an advantage they can expect to rely on their country being more innovative (or offering cheaper labor, or their citizens working harder or…) than all the other countries in the world.

Innovation has been an advatage for the USA. It should continue to be an advantage for the USA but many other countries will innovate very well (Japan, Germany, China, Korea, Singapore, England…). The USA has many assets: transportation infrastructure, banking, rule of law, educated and skilled workforce, huge market, decent tax laws, engineering education… The key will be to keep focusing on the whole system (and fix things like huge budget deficient, huge current account deficit, excessive health care costs, excessive executive pay…).

I also believe a key competitive advantage will be in applying management improvement concepts such as lean manufacturing. continue reading: Is Innovation Needed to Keep Manufacturing in the USA? - Trust: Respect for People

Management then vowed that this (layoffs in 1950) would be the first and last time such an event would come to pass at Toyota, and, in a gesture of respect to former employees, Kiichiro resigned from his position as president of the company.

A bit different than laying off tens of thousands of workers and then taking huge bonuses [the broken link was removed]. And in case you don’t know, I think Toyota’s approach is more honorable and what should be aimed for (I wouldn’t say the president always should resign but it should be a significant admission of failure).

Does this mean no workers ever come into conflict with Toyota management? No. But Toyota’s respect for workers is qualitatively different than that of most companies.

Related: Bad Management Results in Layoffs continue reading: Trust: Respect for People - Ex-Toyota Manager Consulting with Porsche in 1994

While respect for people is an important part of the Toyota Production System, the practice of former Toyota managers were often the "tough love" variety. Today, many people are often too timid, in my opinion, to call out things that need to be improved for fear of making someone uncomfortable. Where that balance properly lies though is based on the culture of the organization (and what needs to be done - occasionally there is a need to "shake people up" in order to make change take place more effectively). continue reading: Ex-Toyota Manager Consulting with Porsche in 1994 - Supplier Development Article

- Quality and Innovation

I really don’t understand how people can talk about innovation as if it were some new discovery. Yes I understand we can bring a different focus to innovation. We can reconfigure management structures to encourage and support innovation. That is good. And new ideas are being developed, but the innovation fad is silly. And accepting the notion that this innovation stuff is some new idea will make managers less effective than if they understand the past.

New Economics by W. Edwards Deming, published in 1992, page 7:

Does the customer invent new product of service? The customer generates nothing. No customer asked for electric lights… No customer asked for photography… No customer asked for an automobile… No customer asked for an integrated circuit.

Innovation has long been important to those interested in management improvement. continue reading: Quality and Innovation

|