Posts selected fromManagement Blog - Engineering Blog - Investing Blog and other blogs - Management Improvement History

I do believe we need to improve our practice of Quality (and to do that we need to understand what happened in the past and why it was not more successful). The idea that Design of Experiments (DoE) was at the core of some Quality Movement to me is not at all accurate.

In my experience only a few Quality professionals today understand what it means and how it should be applied. The idea that it was common place in the 40’s I seriously doubt (though I don’t have first hand knowledge of this). I find it difficult to believe we would have decided to stop using DoE if it was commonly done previously. The understanding I have from those that should know (like George Box and previously my father – Bill Hunter) is that it was not at all common practice and still is not outside of a few industries and even there it is isolated in the domain of a few experts.I do have first hand knowledge of the 80’s and the idea that we did “employee training in problem solving, team activities and just-in-time inventory” well is not even close to accurate. We sent people to training on these things but other than JIT inventory the effectiveness of these efforts were poor (with a few exceptions that really did well).

“Quality” is not being practiced anywhere close to the level with which I am satisfied with in more than a few organizations. We have huge improvements to make in the practice of DoE, SPC, process improvement, having decisions made by the appropriate level (as close to the issue as possible), leadership, teamwork, data based decision making, the use of basically all the Quality tools, systems thinking, transformation… continue reading: Management Improvement History - Fast Company Interview: Jeff Immelt

My guess would be that what lead to this quote is not a lack of understanding that managers need the same qualities today they needed 10 years ago but the compulsion to feed the media frenzy for some incredible new insight. It just isn’t sexy to say “we need the same leadership qualities we needed in the past.” Deming stressed the importance of these “new” qualities he states more than 50 years ago and I think most decent managers have know you need to “know why we’re doing them”

...

Customer focus and innovation would also be at the top of the list of important issues and were 10 years ago and will be 20 years from now. What is important for management does not change much.

occasionally innovation is so dramatic it drastically changes the practice of management, two examples:

1) the use of information technology

2) the whole quality movement [Deming’s ideas, SPC, Toyota/Lean, Six Sigma… continue reading: Fast Company Interview: Jeff Immelt - Design of Experiments in Advertising (2005)

It is great to see the application of Designed Experiments increasing. I am reminded of an article by my father, William G. Hunter, from 1975: 101 Ways to Design an Experiment, or Some Ideas About Teaching Design of Experiments. Examples of the topics of the designed experiments his students performed:

- taste of stewed chicken

- toys child chose to sleep with

- quality of ground malt for brewing beer

- distance football was kicked

- absorption characteristics of activated carbon used with municipal waste water

continue reading: Design of Experiments in Advertising (2005) - Six Sigma Pitfalls

When people say “Six Sigma is great” or “Six Sigma is a waste” often they are talking about different things. But because in both instances “Six Sigma” is used people believe that the meaning must be the same in both cases. It often isn’t. While I find some Six Sigma efforts, books or consultants very useful many others (that also use the words “Six Sigma”) do not offer much of value.

What exactly is meant by “Six Sigma” varies quite a bit. And execution is critical to what makes one program succeed and another fail. continue reading: Six Sigma Pitfalls - Deming and Six Sigma

I agree aspects of Six Sigma are bad. I also think some aspects of Six Sigma are good. And I think the same things about TQM.

continue reading: Deming and Six Sigma - Statistical Techniques for Quality

As six sigma has taken the business world by storm in the past 15 years, many organizations have focused on acquiring and implementing the DMAIC methodology with performance benchmarks defined by “sigma levels”. However, after perhaps proclaiming the “six sigma organization” label for the company, it is important for the business leaders to look beyond immediate concerns, i.e. those issues embodied in black belt projects, and adopt holistic and forward-looking perspectives in seriously advancing organizational interests.

continue reading: Statistical Techniques for Quality - Box on Quality

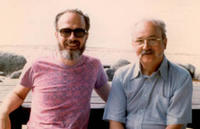

Dr. George Box is not as well known in the general management community as his ideas merit (in my biased opinion – photo of Bill Hunter and George Box). He is well know in the statistics field as one of the leading statistical minds. Box on Quality is an excellent book that gathers his essays from his 65th to 80th year. continue reading: Box on Quality - Government Lean Six Sigma

Once the political decision has been made to eradicate polio then that desire can be carried out – and politics really has little impact. Other examples are not as simple. A political decision to eliminate AIDS runs into political controversies in selecting the best strategies to accomplish the goal.

A desire to eliminate hunger, poverty or homelessness run into differing opinions on how those problems should be addressed. I can’t imagine any politician against the elimination of those problems. However, many politicians will be against various tactics to accomplish those goals.

Political decisions have management components but arguing about the poor management effectiveness of political decisions is a bit too advanced for our current capability, I believe. It seems silly for a government to subsidize mansions being built in hazardous areas where insurers would not insure construction, but for political reasons it continues. It seems silly to have the political leadership prohibit the government from negotiating lower drug costs from suppliers, but they do. continue reading: Government Lean Six Sigma - Management Improvement Flavors

Some tools are much more common in one program, even if they are not limited to one program (such as Design of Experiments used heavily in six sigma). But design of experiments existed long before six sigma and was used by sensible people to improve for decades before six sigma.

The biggest difference I see in the programs is the overall aim. And that overall aim affects everything else. I happen to be a fan of Deming’s ideas. Most of these programs take a great deal from Deming’s ideas. I believe Lean is closest to Deming’s ideas (which makes sense as Lean is essentially the Toyota Production System TPS). continue reading: Management Improvement Flavors - Agility vs. Six Sigma

Some people dislike the idea of managing processes. In my experience they then invent the idea that slow, boring process improvement is an alternative to innovation. That is just wrong. Process improvement should be part of a well run system, as should innovation. Deming, who many believe focused only process improvement, knew the importance of both. See several of Deming’s ideas on innovation. continue reading: Agility vs. Six Sigma - Six Sigma Won’t Fix Bad Management?

Like most management concepts how it is applied varies tremendously. If one just uses some tools that are part of the “Six Sigma tool kit” (mostly tools from TQM and the like) then you might improve bad management only marginally.

But if you read the work of Roger Hoerl, Soren Bisgaard, Forrest Breyfogle III… and learn and apply what they talk about as Six Sigma you will definitely have to address bad management practices. Their Six Sigma is definitely a management improvement system (you can’t apply their concepts of Six Sigma without fixing many bad management practices). continue reading: Six Sigma Won’t Fix Bad Management? - Using Design of Experiments

Design of Experiments can seem complicated but at the core it is fairly simple and powerful. By applying the proper techniques it allows you to gage the effect of several variables and, very importantly, the interactions of those variables with a small number of experiments (or tests or pilots).

George Box is a wonderful author (and friend) who can write for mangers who are not knowledgeable about statistics and statisticians. Statistics for Discovery does a good job of explaining how organizations should use experiments to improve. continue reading: Using Design of Experiments - Six Sigma and Process Drift

- Lean, Mean, Six Sigma Machines

What management claims as the reason for results is not necessarily actually the reason (and this is true not just if they say forced ranking is good [which I disagree with] or lean thinking is good [which I agree with]).

A great difficulty in evaluating management concepts is that the complexity (including interaction) makes it very difficult to determine the results of specific management decisions (separating out the effects of one or several decisions from the hundreds that were made and outside influences, etc.). How much of the success of Google is due to the 20% “engineer time.”Can you calculate the return? I don’t think so. But you can make a judgment that it is a benefit. continue reading: Lean, Mean, Six Sigma Machines - TQM for the Water Business

Deming did not like the term TQM. It was not defined, so each person using it meant something different. And the faddish nature of the term drew a large number of “hacks” (consultants who spoke with authority but without knowledge). Seeing the term TQM used now [2006] however, I find refreshing. To use the term TQM you must go against the temptation to talk only about the current fad (learning organizations, reengineering, balanced scorecard, six sigma, lean…). This author defines what he means by TQM... continue reading: TQM for the Water Business

|